I decided to try my hand at making a skyline diffuser out of scrap wood and cheap furring strips etc. My goal is to learn how to use my wagner paint sprayer, an orbital sander and general DIY skills before tackling some other projects like a subwoofer kit or crown molding.

The tools I used were miter saw (which I bought for my mininalist screen wall project). A Wagner painter sprayer. An orbital sander. Wood clamps. All the tools were purchased on Facebook Marketplace.

I purchased furring strips from Home Depot, after I tried some pine fencing wood from Lowes. The fencing wood was not the best product to use, but it was the cheapest pine I could find. My goal was to stay around $40 for the wood and stain. I bought 1 piece of 1/2 plywood for the base.

I watched several YT video's of various skyline projects and got a general idea of the project.

Here's the page to create the dimensions of the columns and platform for the diffuser

http://www.mh-audio.nl/Acoustics/DiffusorCalculator.asp

First step, sanding down the lumber. I used an 80, 120, 220 for each pass. If possible I suggest sanding and cutting outside to keep the mess to a min.

Next step was to stain the wood. I wanted a more paint like finish since I was doing black vs a rustic look (which wouldn't fit as well with my HT). I tried a non-transparent, then switched to semi-transparent for the second diffuser. I decided to cut the wood after painting to make the painting process easier. There is a downside, which I talk about.

Once I knew how many individual pieces I would need, I went about making the cuts. I was making about 200 cuts per diffuser. To make sure I had the right size for each, I used a stop block clamped to my miter saw. The cutting gets a little monotonous. Don't let down your guard or you could lose a finger...which adds to the time to complete the diffuser and yes, you'll have less fingers to work with.

Here's the lack of experience on my part. Using this cheaper wood may have been the issue, or the fact I painted first or I need a different miter blade...but when I'd make the cuts, I get the "fraying" or rough cut on the edges of the pieces.

After the cuts were made, I'd sand down the sides with the "fraying" on the sides and top to create a smooth finish. This part of the project was the worst. After sanding, I used the card board "bottoms" from cases of soda or drinks that you'd buy at Costco (card board trays) to situate the individual pieces for the touch up paint on the sides and now the newly cut tops. If I just set them on a paint tarp, the pressure of the spray gun would send them rolling across the floor, so using the trays helped keep them in place.

Once everything was painted, including the base of the diffuser, I started the gluing process. Tips for gluing: Use a glue brush vs finger. I glued the sides that weren't exposed and the bottom for an overall secure fit. I found Titebond glue the best product (the thicker fast dry was my preference). I would lay out each row bottom to top vertical row..one at a time. I kept the pieces grouped by size, so I counted the number of #1's go to my other table and grab those, number of #2's etc etc. otherwise you can get confused or lose your place.

After completing the gluing on the first diffuser, I realized it looked somewhat unfinished. I had some scrap 1x2" pine boards from a previous project. I cut pieces to created a frame around the base. I used a butt joint, gluing the bottom and tops to the base (then clamping). Once those framing pieces had dried, I secured the sides using a 1 1/2 inch all construction screw. I wanted the strength and security of the screw, since I would be screwing the french cleats into the frame for mounting.

Finally, I used some tak cloth to remove any wood residue and then touch up paint.

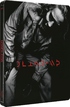

I've attached a picture of the first diffuser. The mistakes I made from the first one, I incorporated those changes into the second one. One big change is framing the base, BEFORE gluing the column pieces. I finding the frame helps guide the placement for a more finished look. The first diffuser is functional, but I wouldn't want a close inspection. This second unit has more finished look to it, after I learned when not to rush and tricks to avoid the initial mistakes.

Ron

Threaded Mode

Threaded Mode