Now - handling the bass modal ringing......

Driving home from work, after my lunch Home Depot visit, this idea came to me.

Why not use thd rod for the moveable SuperChunk design?

It could easily work, no flexing/warping ever.

Pict is pretty self explain, bottom and top are piece of wood - thick mdf comes to mind.

You can make the 3 rods "invisible" by having then @ the corners and wrapped, or you go with an "industrial look" and have the 2 outside corner ones visible. I show a rod connector in blue, since I think normal Home Depot thd rods are not 9' long.....

[edit 2-18-2011; thd rod comes in 6' length max at Home Depot / Lowes]

I'm sure with little looking I could get my hands on some from a local supply house.

Here's what I've got so far on my rear broadband bass traps.

Each stack is (6) sheets of 2" thick 2' x 4' OC705 panels, cut 24" x 24" x 34".

The 24 triangles stack just over 48" high, I've decided to make them removable "corner tables".

The base board mldg will be removed and cut down after these done, so it will look integrated nicely.

fwiw: I have some more....Star Trek stuff to display, the 3D chess set, some ST:TOS replica phaser and tricorder, etc, collected over 20+ years.

So, the top will be nice wood, while the bottom possible mdf or even some leftover OSB I have. The 1/2 thd rod comes in 72" size.

Now, above that display zone, which will get light w/o shadows via the sconces, will either be a 17" x 17" x 24" superchunk as shown on LH side, or a more visually pleasing triangular patch as shown on RH side, tbd.

Note: That Home Depot bag on the center table has (2) blue box AC gang boxes, I was going to move those sconces today fwd about 8" so I could have floor-ceiling "big" superchunks, but by putting a table top I've decided to not to do that.

(the boys and I watched a movie last night, sorry for the clutter)

Regarding cutting the superchunks out of the 2' x 4' sheets, I started with the big bread knife, did 4, then tried the electric turkey knife.

My experience, the manual knife was MUCH easier to get dead straight and perpendicular lines cut, the electric knife seemed to walk on its own slightly, giving a wavy edge, not style points.

Here you can see what I'm talking about.

The bottom 4 were cut by hand/bread knife, the next 4 by electric knife.

It's not that much more time for hand/bread knife, 1st pass with edge guide sets the line, then 4 more passes holding the knife at a low 15-20 degrees gives perfect straight and perpendicular edge.

I suppose a jig could be made to ensure the electric knife is straight and perpendicular, but this manual method worked for me easily.

via makeshift paint/infra red warm booth I'm painting the thd rods......and the attach nuts/washers

.

2nd coat of paint on the thd rod and hardware in the garage

-final cut/paint the OSB base.

I added a 1 1/4 perimeter of 3/4 OSB so the thd rod/nuts won't be resting on the floor directly. Painted green, same as walls.

-Final cut/sand/stain the birch top board

These "Mikes Mondo Corner Bass traps", each will weigh 50+ lbs, looking back at my original plan of 1 huge removal bass trap.....nope that's 100+ lbs of weight, glad I went "1/2 size" then an additional trap in the top corners

they are huge, big, and sturdy

(YouTube video clip will show that)

Layout the cut big triangles, cut back corner 3" x 3" 45 deg for clearance to rear thd rod

Stack 'em, trying to keep the leaning tower straight/aligned as it gets higher...

Me next to my the 4' stack, showing size of this beast.

However, mistake I made was NOT putting the rods in 1st before loading the triangles, so I had a PIA to get the rods in...lesson for #2

After fiddling here are the rods installed

.

I did NOT pre-cut the thd rod in the garage, had no way of knowing how much the OC705 would compress.

I actually can compress easily 1", more than 2", but the 1/2" birch ply top flexes too much at 2", I settled on 1" of compression, it felt very sturdy and solid.

Green tape for cutting spot, my wife held the rod top while I used a Dewalt 18v buzzsaw.

Load in room, check for ingress/egress of loading the trap etc.

No other issues appeared to prep for fabric covering time

.

Cut the mid-hi freq blocker (kraft paper here) for the front face, install and hold with simple 1 3/4" craft pins

Cut the 56" wide fabric (roll size), for this first one I cut just 3/4" extra top/bottom (to 50", compress size is 48.5 "), it worked but for the 2nd one I increased that to 1" top/bottom extra for wrapping safety.

I should say this is a GLUE-LESS/PIN-LESS build for the fabric, I just use pins for the top to start, put the top birch ply board down and compress/tighten, keeping fabric not attached, and tuck the fabric in at the bottom.

1st one "done", front face side

.

Backside looks good, needs covering

Now, the 2nd one went much quicker and smoother!

Make a 3 rod frame with base and top, gave 5" extra for loading.

This worked best for aligning the loose big triangles for flatness.

Kraft paper installed on 2nd bass trap:

Close-up showing 1" of extra material on the top before clamping down the birch ply.

2nd one done, and backside covered

.

Loaded into the HT room, RH side one is the 2nd one made, it came out a little better.

YouTube video of them,

http://youtu.be/lvBGTn4oXJI

Upper bass traps:

Plan A:

"smaller" triangles 17" x 17" x 24".

I was just going to build these, then I was wondering about what was the largest size I could build/fit up there?

Plan B:

I'll call this the "Trapezoid wedgie bass trap", consists of smaller triangles 17" x 17" x 24" blending into the biggie 24" x 24" x 34" to get more low freq absorption.

The thd rod will be hidden inside the bass trap except will show on the bottom.

I'm 90% going with Plan B, I think it will look nicer up there and the hidden rods is better for the upper location.

Unless I move those sconces full 24" x 24" x 34" size won't fit.

Additional 1/2" Birch plywood and thd rod/hardware bought yesterday.

This afternoon is build time.

I've got an idea on hidden holding system, will work on it a little more and if its doable will go with that.

btw, not all the Star Trek stuff will stay there, it will be de-cluttered, just showing my kids some of the stuff I had back in the day.

And YES, those Star Wars glasses are original Burger King glasses from the early 1980's, and those are genuine Apollo 13 glasses as well.

Unfortunately, Leonard Nimoy has not signed my "I am Not Spock" book...

2) "Trapezoid wedgie bass trap's" frames cut, stained, painted blk thd rod/hardware, assembled.

When you tighten the nuts up there is very little flex in this assembly, even prior to having the insulation in it.

There are other ways to make these obviously, but the thd rod IMO is easy, simple, and adjustable.

They are shown upside down here, that is how I'll cut/load them, starting from the big 24" x 24" x 34" triangles, and blending into the 17" x 17" x 24" as last one.

The 3/8-16 T-nut's worked perfect, nice and flush for ceiling mtg.

I'm needing more OC705 or the new stuff , ECOUSTIMAC Eco Friendly DIY Insulation.

I need (6) sheets of 2" 2' x 4' panels for these 2 bass traps, then I need (18) more sheets of same for my front wall bass traps...I'm, leaning towards the ECOUSTIMAC stuff.

1 done with material stacking, added loose pieces with sticky spray, worked great.

Putting on the Kraft paper to block mid-hi frequencies:

.

.

1st one wrapped and done!

Those drywall edges made all the difference, I'm going to add those as lesson learned to lower bass trap post. Much crisper look.

.

Installing into the HT room.

I used a 30+ year old hydraulic bottle jack as 3rd hand...

Both installed

Detail LH side....................................RH side

.

The upper bass traps are just sitting on (2) L brackets each, gotten from Lowes in the outside deck building area, painted them green.

By simple geometry they are trapped up there, not even attached screws to lower wood piece.

I did put 3/4" round felt on the top/ceiling piece to space it off the ceiling and ensure no vibrations.

Also on the wood edge to space it off the back/side walls, no issue with vibrations at all.

.

That completes the Rear wall broadband bass treatments.

Now some front wall broadband bass treatments

A quick re-cap on my Front wall corner superchunk with "green" material, these were built 4/2011 thru 6/2011...slow but steady:

Cutting lots and lots of 24" x 24" x 34" triangles....nice to have non-itchy stuff.

Made a mid-support from 3/4" OSB to hold 2/3's of them 36" off the floor.

I did this as part of my front fabric mounting strategy as mid-support of the drywall corner edging and also just in case I ever wanted to tuck a sub there for whatever reason.

.

Top ones stacked

I realized the front wall speaker wires and side wall subwoofer coax needed to be moved....when building the HT I did not know about bass traps.

Cut and re-locate to 29" from the corner....use scrap wood as backer....tape/mud/paint....everything takes time.....

Instead of making a fabric frame, I used drywall corner edge and wrapped the fabric behind that.

Bend them from 90deg to 45deg by hand, went ok.

Also, used kraft paper to reflect mid/hi freq like my other bass traps, just cut and tuck tight.

The fabric was cut with 4" extra top/bottom, and 2.5" each side.

Initially I pinned the top for hanging, then tucked that under the ceiling.

Used plastic putty knife to tuck the sides.

I designed the drywall edge to be 1/8" off the wall, and then tucked the fabric behind that and the cut triangles.

A decent friction fit that stretched taught.

Done and absorbing some of those reflecting LFE!

This method was easy to do, an alternative to making the fabric frame and mounting that.

Picture is worth 1000 words.....

this simple pict should help visualize what I did above, excel can be useful for quick sketch...

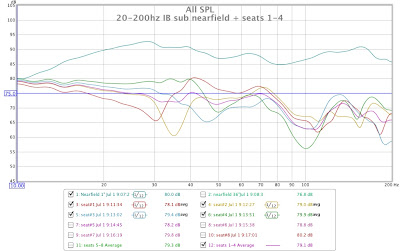

2nd row is almost deal flat across the LFE zone, 1st row not as good.

I also did freq listening of sub test tones with the RS db meter to grasp the chart to real life, a worthwhile thing to do, helps tie graphs to sound.

I had "leftovers" acoustic material from what I did earlier this year(2011), sitting in my utility room for months.

Wanted to improve the 1st row bass to be more consistent across seat-seat.

Yesterday (Saturday Dec-17-2011) I built a broadband bass trap that goes above my screen.

Basically 2' wide x 4' long panels that straddle the front wall/ceiling space.

I wanted a bigger trap, but due to the screen height and front lights this is as big as possible.

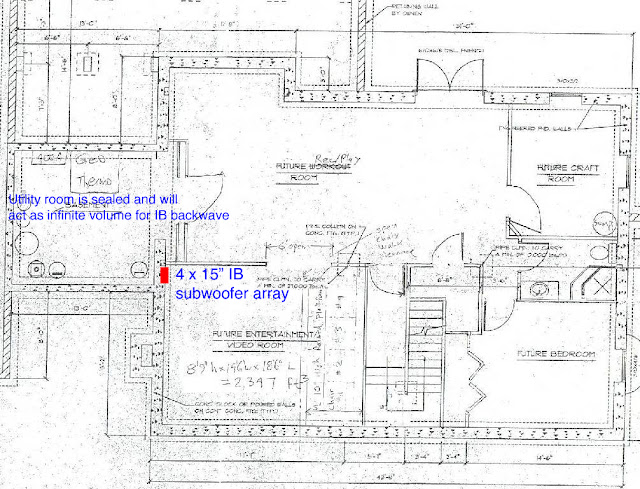

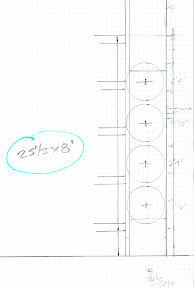

(LH side already has "big" superchunk style trap, 34" x 24" x 24", and RH side is IB subwoofer)

Construction method:

Bonded kraft paper to the front, and mounted them with just air gap for now.

I've got a roll of pink fluffy fiberglass that later I will put behind each one.

My plan is simply put a paper coated drywall corner edge on the top/ceiling edge, and then roll/fold the green burlap for a seemless look like I did the LH trap.

I realize not "by the book" of having the same gas flow resistivity porous material for a broadband bass trap, but since I had the materials lying around if some "free" improvements can be had why not.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.  .

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

)

)

I'm guessing your audio/video experiences are like you're on

I'm guessing your audio/video experiences are like you're on

Linear Mode

Linear Mode